hardness test vs impact test|hardness testing instrument : importers Impact Strength. Impact strength is measured by allowing a pendulum to strike a grooved machined test piece and measuring the energy absorbed in the break (AS1544). About Press Copyright Contact us Creators Advertise Developers Terms Privacy Policy & Safety How YouTube works Test new features NFL Sunday Ticket Press Copyright .

{plog:ftitle_list}

Os Resultados do jogo do bicho do Rio de Janeiro são atuali.

What's the Difference? Charpy Impact Strength and Hardness Test are both mechanical tests used to evaluate the properties of materials, but they measure different aspects. Charpy . Films. Rocks and minerals. Importance of Hardness Testing. Hardness testing is important for a number of different reasons. The hardness of a material can be a critical parameter in its application. This can be the case .

compression test 22re engine

Kamal Dwivedi June 15, 2021. Hello friends, Today we are going to talk about types of hardness testing methods and impact testing. Hardness tests are used to determine the hardness of any materials and impact testing is used for . Impact testing is a critical evaluation process that determines a material or product’s toughness, resilience, and durability when subjected to sudden forces or shocks. . Impact Strength. Impact strength is measured by allowing a pendulum to strike a grooved machined test piece and measuring the energy absorbed in the break (AS1544).

6 Types of Mechanical Tests. Tensile testing. Compression testing. Hardness testing. Impact testing. Fatigue testing. Torsion testing. Conclusion. The term “mechanical testS” refers to the process of measuring .

compression test 240

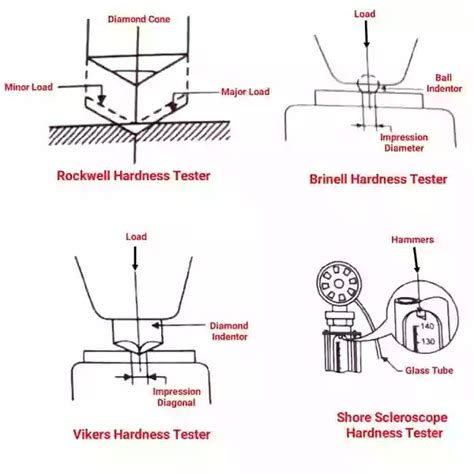

1 Rockwell Hardness. The Rockwell hardness test measures the depth of penetra-tion of an indenter into a material under a known load. It provides a hardness value based on the depth .Impact testing measures the material’s ability to absorb energy when fractured at high velocity. This gives an indication of the ‘toughness’ of the metal and two methods are usually employed . The ductility and strength (measured by a tensile test), related hardness properties and fracture toughness (or impact resistance) are the three most frequently required materials properties.The Charpy impact test is a widely known test famous for its accuracy in measuring metallic and plastic materials. SB Russell and George Charpy introduced this in the 20th century to measure the strength of the material.

compression test 240sx

The Charpy impact test (Charpy V-notch test) is used to measure the toughness of materials under impact load at different temperatures! Test setup and test procedure. In the Charpy impact test, a notched specimen is .

Impact testing is a convenient method for investigating high strain rate behavior, but there is a need for accurate and precise data collection. Here, we combine the precision and accuracy of the . The impact hardness test methodology is described in Figure 1. An indenter retraction distance of 6µm and a step force of 6mNIt is typically measured by the amount of energy absorbed by a standard specimen during a pendulum impact test. On the other hand, Hardness refers to a material's resistance to indentation or scratching. It is determined by measuring the depth or size of an indentation made by a standardized indenter under a specific load. While Charpy Impact . Discover impact testing methods like Charpy, Izod, and drop weight & learn how they ensure material safety, toughness, and reliability across industries. . Rockwell hardness test standards. ASTM D785, ASTM E18, ASTM E140. .There are many kinds of tests performed to conduct testing of hardness. Testing of hardness is done by observing a steel ball pressed against the other material’s surface under tremendous pressure. Testing of hardness is done through the Rockwell Hardness test and the Brinell Hardness Test. There are also different types of hardness tests.

Different materials testing standards, such as ASTM E23, ASTM A370, and ASTM D256 govern the exact testing procedure and test specimen requirements for each type of impact test, and for different material groups (e.g., metals vs. plastics). While an impact test can help characterize a material’s ability to withstand sudden loads, the impact .

Impact test. Many materials, sensitive to the presence of flaws, cracks, and notches, fail suddenly under impact. The most common impact tests (Charpy and Izod) employ a swinging pendulum to strike a notched bar; heights before and after impact are used to compute the energy required to fracture the bar and, consequently, the bar’s impact strength. In the Charpy test, the test .

Impact testing serves to assess a material’s impact toughness, representing its resistance to impact forces. The ability to quantify the impact property is a great advantage in product liability and safety. This involves three main tests: the tensile impact test, the Charpy V-notch test, and the Izod impact test. Engineers use the Charpy .Impact Test: This type of testing is used to find the toughness of metal by using an impact test machine. in this process, there are two methods like Charpy test and Izod test.To test the work-piece/specimen notched bar should be done according to the standards when the work-piece is placed in the path of a lever attached with weight as shown .

mechanical hardness test

impact and hardness testing

The size and depth of the indentation formed are recorded. The hardness data is empirical; hence it varies for different testing processes (e.g., Brinell Hardness number, Knoop Hardness, Shore Hardness, Rockwell Hardness Test, and Vickers Hardness Test). This test proves the resistance of the subject to permanent deformation. 5. Torsion TestA Vickers hardness tester. The Vickers hardness test was developed in 1921 by Robert L. Smith and George E. Sandland at Vickers Ltd as an alternative to the Brinell method to measure the hardness of materials. [1] The Vickers test is often easier to use than other hardness tests since the required calculations are independent of the size of the indenter, and the indenter .

Impact testing measures the material’s capacity to absorb energy when ruptured at high velocity. This gives an indication of the strength of the material and two methods are usually used for impact testing, Charpy or Izod. Hardness testing assesses the impact of the metal or alloy to permanent indentation, and the depth or size of the indent .

how hardness testing works

The Vickers hardness test is ideal for testing of all metals and is therefore the method with the widest range of application. The hardness test method according to Vickers is described in standards ISO 6507 (Metallic materials – .The difference between these two properties, and hardness too, are well illustrated by stress-strain curves derived from a tensile test. The line of a material under stress will move linearly, stress (y-axis) and strain (x-axis) . In Rockwell hardness testing, HRA, HRB, and HRC represent three different scales: Scale A, Scale B, and Scale C. The Rockwell test is a common indentation hardness test. All three scales begin with an initial .

The Charpy impact test is still used throughout sectors to assess material toughness, from construction and manufacturing to engineering and beyond. This test offers practical insights into how materials respond to sudden, dynamic impacts. Even as businesses change, the Charpy impact test is still a valuable and essential tool.

Hardness testing to Brinell is mainly performed with HBW 1/30 or HBW 2.5/187.5. For hardness testing to Rockwell, scale B (HRB) is used for fasteners of property class 4.6 - 6.8 and scale C (HRC) for property classes 8.8 - 12.9. In the event of arbitration, the Vickers hardness test shall be used as reference.Similar to the Charpy Impact test, the Izod Impact test is a method used to measure the energy absorbed by a notched specimen when it is struck by a pendulum. It is commonly employed to test the impact strength of materials, especially plastics and polymers. During the Izod test, the sample is impacted in a vertical orientation at room temperature.

Order custom essay Hardness Tests And Charpy Impact Test with free plagiarism report 450+ experts on 30 subjects Starting from 3 hours delivery Get Essay Help. Hardness is a measure of a material’s resistance to localized plastic deformation. It also is one of the important properties to be considered. . General Purpose Testing: Vickers hardness testing is versatile and well-suited for general-purpose hardness testing across various industries and applications. When to Use Knoop Hardness Testing Testing Brittle Materials. Knoop hardness testing is best suited for testing brittle materials, such as ceramics, glass, and thin films. The most common types of mechanical tests include Tensile test, Compression test, Hardness test, Impact test, Fatigue test, and Torsion test. Tensile testing. Tensile testing is a type of mechanical test used to measure the properties of a material when subjected to tensile forces. The test involves applying a controlled load to a sample of the .

General characteristics of hardness-testing methods and formulas for calculating hardness. Hardness Scale. The chart below is used for converting various hardness scales. Since all the hardness test are limited in range. . The Charpy impact test, also commonly referred to as the Charpy V-notch test by material scientists, serves as a .

Instead, the optimal wear performance is obtained with a combination of high hardness value and high impact toughness value as well. Even so, from Fig. 10 it can be seen that the hardness is the most important parameter as it is confirmed with the good correlation value between the hardness and impact wear mass loss (correlation of 92%).The standard testing method involves pushing a diamond pin down onto the material’s surface and measuring how far the pin goes down the cross-section. The depth that the pin travels is inversely proportional to hardness. Tensile Strength vs. Hardness. Common concerns with hardness testing are accuracy and repeatability. The Vickers hardness test can use a test force greater than 980.7N;2. The micro Vickers test force is recommended. Characteristics and Application of Vickers Hardness

compression test 240z

compression test 3.2l dodge intrepid

• Sarabhai vs Sarabhai• Wagle Ki Duniya – Nayi Peedhi Naye Kissey• Gulabo Sitabo Ver mais

hardness test vs impact test|hardness testing instrument